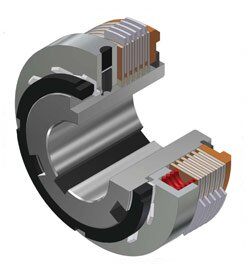

Multiple Disc Mechanical Clutches (MMS/MMD)

Carlyle Johnson's Mechanical Multiple Disc mechanical clutches provide 3 to 6 times the torque produced by a single disc mechanical / friction clutch of the same package size, making them the ideal solution for high torque, limited space requirements.

Separator springs are used between each pair of inner discs on these mechanical clutches, providing the advantage of truly floating discs. This ensures that there is negligible drag, no abrasion, and consequently no heat generated when the clutch is in neutral. A locking plate on the disc end of each unit (two on double types) locks all discs against compression by the lever system.

As with all Carlyle Johnson products, our multiple disc mechanical clutches can be customized to meet your applications. Our engineering department can also custom-design and produce a mechanical or friction clutch to fit your exact requirements.

Specifications / Dimensions

| Clutch # | HP at 100 RPM | Dyn. Torque (ft/lbs) | St. Torque (ft/lbs) | Axial Sleeve Pressure (lbs) | I Body Bores (+.001) | I Body Bores (-.000) | Keyway |

|---|---|---|---|---|---|---|---|

| 20** | .100 | 5 | 10 | 15 | 1/2 | 5/8 | ** |

| 21 | .250 | 13 | 26 | 20 | 3/4 | 7/8 | 3/16 x 3/32 |

| 22 | .500 | 27 | 54 | 30 | 1 | 1 1/8 | 3/16 x 3/32 |

| 23 | 1.000 | 53 | 106 | 30 | 1 1/4 | 1 3/8 | 1/4 x 1/8 |

| 24 | 1.750 | 92 | 184 | 40 | 1 1/2 | 1 5/8 | 5/16 x 5/32 |

| 25 | 3.000 | 158 | 316 | 60 | 1 3/4 | 1 7/8 | 3/8 x 3/16 |

| 26 | 5.000 | 263 | 526 | 80 | 2 | 2 1/4 | 7/16 x 7/32 |

| 27 | 10.000 | 525 | 1050 | 105 | 2 1/2 | 2 3/4 | 9/16 x 9/32 |

| 28 | 15.000 | 788 | 1576 | 150 | 2 3/4 | 3 | 9/16 x 9/32 |

| Clutch # | Disc Lugs | Sngl A |

Sngl B |

Dbl B |

Sngl/Dbl D |

Sngl/Dbl J |

Sngl/Dbl K |

Sngl/Dbl L |

|---|---|---|---|---|---|---|---|---|

| 20** | 3 | 2.594 | 2.375 | - | .375 | .375 | .855 | 2.125 |

| 21 | 3 | 2.594 | 3.000 | 4.750 | .375 | .500 | 1.125 | 2.125 |

| 22 | 3 | 3.188 | 3.469 | 5.531 | .438 | .500 | 1.281 | 2.625 |

| 23 | 3 | 3.938 | 4.031 | 6.469 | .531 | .625 | 1.469 | 3.125 |

| 24 | 3 | 4.250 | 4.031 | 6.469 | .531 | .625 | 1.469 | 3.563 |

| 25 | 8 | 4.938 | 4.813 | 7.719 | .609 | .750 | 1.719 | 4.063 |

| 26 | 12 | 5.469 | 5.000 | 8.094 | .609 | .750 | 1.719 | 4.625 |

| 27 | 12 | 7.469 | 6.344 | 10.438 | .875 | .812 | 2.063 | 6.500 |

| 28 | 12 | 8.625 | 6.563 | 10.875 | .875 | .812 | 2.063 | 7.500 |

| Clutch # | Sngl N |

Sngl/Dbl OM |

Sngl P |

Dbl B |

Sngl/Dbl Q |

Sngl/Dbl SM |

Sngl/Dbl VM |

Sngl/Dbl X* |

|---|---|---|---|---|---|---|---|---|

| 20** | .063 | 1.313 | .563 | .125 | 1.984 | 2.188 | *** | 2.125 |

| 21 | .063 | 1.641 | .625 | .024 | 1.984 | 2.188 | 5/16 -18 | 2.125 |

| 22 | .063 | 1.938 | .703 | .016 | 2.484 | 2.750 | 5/16-18 | 2.625 |

| 23 | .063 | 2.266 | .797 | .016 | 3.234 | 3.563 | 7/16-16 | 3.125 |

| 24 | .063 | 2.266 | .797 | .016 | 3.266 | 4.063 | 7/16-16 | 3.563 |

| 25 | .094 | 2.719 | .953 | .031 | 4.484 | 4.875 | 7/16-16 | 4.063 |

| 26 | .094 | 2.906 | .953 | .031 | 5.484 | 5.875 | 7/16-16 | 4.625 |

| 27 | .094 | 3.750 | 1.125 | .031 | 6.984 | 7.500 | 7/16-16 | 6.500 |

| 28 | .094 | 3.989 | 1.125 | .031 | 7.984 | 8.500 | 7/16-16 | 7.500 |

| Internal Flange Driving Cups |

||||||||

|---|---|---|---|---|---|---|---|---|

| Cup # | A | B | D | E | H | J* | Mtg. Holes | Slots |

| MMS-0021-106-300 | 2.188 | 1.033 - 1.031 | 1.031 | .188 | 1.500 | 8 | 3 | 3 |

| MMS-0022-106-300 | 2.750 | 1.4395 - 1.4375 | 1.250 | .188 | 1.938 | 10 | 3 | 3 |

| MMS-0023-106-300 | 3.563 | 1.9395 - 1.9375 | 1.406 | .250 | 2.563 | 1/4 | 3 | 3 |

| MMS-0024-106-300 | 4.063 | 2.0645 - 2.0625 | 1.438 | .281 | 2.875 | 5/16 | 3 | 3 |

| MMS-0025-106-300 | 4.875 | 2.5645 -2.5625 | 1.719 | .313 | 3.500 | 5/16 | 5 | 8 |

| MMS-0026-106-300 | 5.875 | 3.627 - 3.625 | 1.906 | .313 | 4.500 | 5/16 | 5 | 12 |

| MMS-0027-106-300 | 7.500 | 4.753 - 4.750 | 2.313 | .313 | 5.813 | 7/16 | 5 | 12 |

| MMS-0028-106-300 | 8.500 | 5.753 - 5.750 | 2.500 | .313 | 6.813 | 7/16 | 6 | 12 |

| Ring Driving Cups | ||||||||

|---|---|---|---|---|---|---|---|---|

| Cup # | A | B | D | H | I | J* | Mtg. Holes | Slots |

| MMS-0020-106-400 | 3.123 - 3.125 | 2.015 - 2.017 | .688 | 2.563 | .343 | 1/4 | 3 | 3 |

| MMS-0021-106-400 | 3.123 - 3.125 | 2.015 - 2.017 | 1.031 | 2.563 | .343 | 1/4 | 3 | 3 |

| MMS-0022-106-400 | 3.623 -3.625 | 2.515 - 2.517 | 1.156 | 0.188 | .343 | 1/4 | 3 | 3 |

| MMS-0023-106-400 | 4.623 - 4.625 | 3.265 - 3.267 | 1.313 | 3.938 | .406 | 5/16 | 3 | 3 |

| MMS-0024-106-400 | 5.123 - 5.125 | 3.765 - 3.767 | 1.313 | 4.438 | .410 | 5/16 | 3 | 3 |

| MMS-0025-106-400 | 6.123 - 6.125 | 4.515 - 4.517 | 1.594 | 5.313 | .531 | 3/8 | 4 | 8 |

| MMS-0026-106-400 | 7.120 - 7.125 | 5.515 - 5.517 | 1.781 | 6.250 | .531 | 3/8 | 6 | 12 |

| MMS-0027-106-400 | 9.120 - 9.125 | 7.015 - 7.017 | 2.188 | 8.063 | .690 | 1/2 | 6 | 12 |

| MMS-0028-106-400 | 10.120 - 10.125 | 8.015 - 8.017 | 2.438 | 9.063 | .680 | 1/2 | 6 | 12 |

In addition to our standard Multiple Disc Air Clutch Units, our engineering department can custom design and manufacture a new component to meet your specific requirements. If you have further questions or would like to discuss your specific needs, please contact us.

Images & Drawings

Features of MMS/MMS Multiple Disc Clutch Units

The MMS/MMD unit's clutch disc features a bronze or steel friction clutch surface for added life, superior consistency for indexing and for excellent torque transmission. Shipped fully-assembled CJM multiple disc mechanical clutches arrive ready to be slipped onto a shaft.

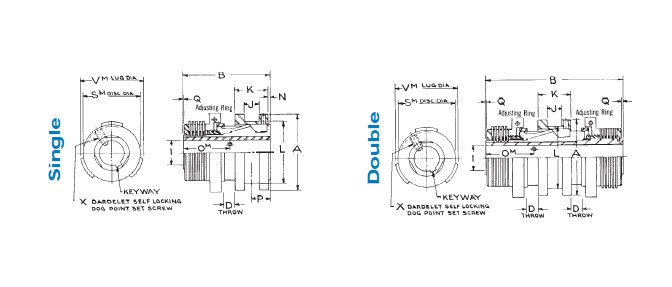

When needed, manual adjustment to the clutch is made by temporarily loosening the lock screw on the split type adjusting ring, then turning the ring to give the desired shifting pressure. Only a hex key wrench is required for this adjustment.

Advantages

- Highest torque in the smallest space

- High performance and long-life

- Simplicity of design, greater adaptability

- "Floating Disc Packs" - reduce drag, abrasion and heat build-up in neutral as well as provide consistent release

- Easy on-line manual adjustment allows for fine-tuning of the device

- Shipped assembled and ready to install

Operation

- Torque range 10 lb. ft. - 2400 lb. ft.

- 1 HP to 150 HP capacity

- Positive engagement / disengagement possible at any speed

- All units run in oil or dry applications

Customization

- Available in single or double type

- Custom designs and alterations available

Downloads

Further downloads including certificates, instruction manuals and product images are available to you in our Download Center:

Downloads