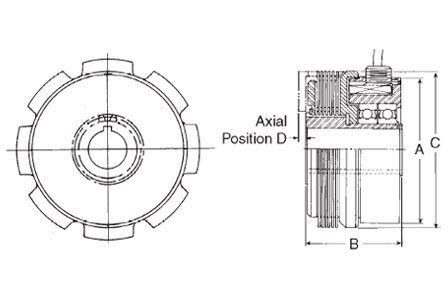

Multiple Disc Electric Clutches (EMA)

Multiple disc electric clutches deliver 3 to 6 times the torque of single disc electric clutches of the same package size. With superior performance and excellent reliability, the multiple disc electric clutch design is simple and rugged, ideally suited for critical applications.

Carlyle Johnson multiple disc electric clutches provide high reliability for mission-critical military applications, including in the U.S. Army's new fighting vehicles, winch mechanisms aboard rescue helicopters, cooling pump drives, bomb hoists, and aircraft deicing equipment. Our electric clutches are also utilized in products that service the medical, machine tool and food packaging machinery.

As with all CJM parts, our experienced engineers can modify our standard electric clutches to meet you needs, or we can design a new product to meet your exact requirements.

Specifications / Dimensions

| Model | Dyn. Torque (lb. ft.) | St. Torque (lb. ft.) | A | B | C | Min. Position D |

Bores | Keyway | Watts |

|---|---|---|---|---|---|---|---|---|---|

| EMA-0265 | 8 | 15 | 2.625 | 2.156 | 2.781 | .188 | 1/2 or 5/8 | 1/8 x 1/16 | 40 |

| EMA-0325 | 8 | 15 | 2.266 | 2.344 | 3.516 | .25 | 1/2 or 5/8 | 1/8 x 1/16 | 40 |

| EMA-0375 | 15 | 30 | 3.797 | 2.563 | 4.047 | .25 | 3/4 or 7/8 | 3/16 x 3/32 | 40 |

| EMA-0425 | 35 | 70 | 4.359 | 2.75 | 4.625 | .25 | 1 or 1 1/8 | 3/16 x 3/32 | 40 |

| EMA-0475 | 75 | 150 | 4.828 | 3.063 | 5.188 | .313 | 1 1/4 or 1 3/8 | 1/4 x 1/8 | 50 |

| EMA-0625 | 150 | 300 | 6.359 | 3.625 | 6.75 | .375 | 1 3/4 or 1 7/8 | 3/8 x 3/16 | 50 |

| EMA-0800 | 300 | 600 | 8.094 | 4.063 | 8.5 | .375 | 2 or 2 1/4 | 7/16 x 7/32 | 80 |

| EMA-0950 | 600 | 1200 | 9.641 | 4.438 | 10.063 | .375 | 2 3/4 or 3 | 9/16 x 9/32 | 90 |

| EMA-1150 | 1200 | 2400 | 11.5 | 5.063 | 11.813 | .375 | 3 1/4 or 3 1/2 | 3/4 x 3/8 | 100 |

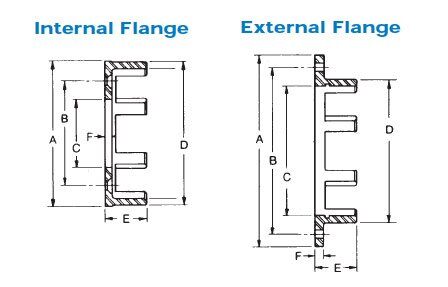

| Internal Flange | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Drive Cup # | A | B (b.c. ) | Screw Size | Holes | C | D | E | F | Slots |

| EMA-0265-106-30 | 2.787 - 2.785 | 1.880 - 1.870 | 10 | 3 | 1.377 - 1.375 | 2.625 | .989 | .188 | 8 |

| EMA-0325-106-30 | 3.526 - 3.560 | 2.567 - 2.557 | 1/4 | 3 | 1.877 - 1.875 | 3.5 | 1.063 | .188 | 8 |

| EMA-0375-106-30 | 4.250 - 4.248 | 3.067 - 3.057 | 1/4 | 3 | 2.017 - 2.015 | 4.188 | 1.188 | .188 | 8 |

| EMA-0425-106-30 | 4.750 - 4.748 | 3.630 - 3.620 | 1/4 | 3 | 2.517 - 2.515 | 4.688 | 1.25 | .188 | 8 |

| EMA-0475-106-30 | 5.520 - 5.248 | 3.932 - 3.932 | 5/16 | 3 | 2.517 - 2.515 | 5.188 | 1.375 | .25 | 8 |

| EMA-0625-106-30 | 6.812 - 6.810 | 5.317 - 5.307 | 3/8 | 4 | 3.767 - 3.765 | 6.75 | 1.656 | .313 | 8 |

| EMA-0800-106-30 | 8.562 - 8.560 | 6.255 - 6.245 | 1/2 | 4 | 4.517 - 4.515 | 8.5 | 1.703 | .313 | 12 |

| EMA-0950-106-30 | 10.062 - 10.060 | 8.067 - 8.057 | 1/2 | 4 | 5.517 - 5.515 | 10 | 1.781 | .313 | 12 |

| EMA-1150-106-30 | 11.812 - 11.809 | 9.817 - 9.807 | 1/2 | 6 | 8.017 - 8.015 | 11.75 | 2 | .313 | 12 |

| External Flange | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Drive Cup # | A | B (b.c. ) | Screw Size | Holes | C | D | E | F | Slots |

| EMA-0325-106-20 | 4.625 - 4.623 | 4.130 - 4.120 | 1/4 | 3 | 3.300 - 3.298 | 3.5 | 1.063 | .25 | 8 |

| EMA-0375-106-20 | 5.625 - 5.623 | 4.880 - 4.870 | 1/4 | 3 | 3.814 - 3.812 | 4.188 | 1.188 | .25 | 8 |

| EMA-0425-106-20 | 6.125 - 6.123 | 5.380 - 5.370 | 1/4 | 4 | 4.314 - 4.312 | 4.688 | 1.25 | .25 | 8 |

| EMA-0475-106-20 | 6.875 - 6.873 | 6.005 - 5.995 | 5/16 | 4 | 4.814 - 4.812 | 5.188 | 1.375 | .25 | 8 |

| EMA-0625-106-20 | 8.500 - 8.498 | 7.692 - 7.682 | 3/8 | 4 | 6.377 - 6.375 | 6.75 | 1.656 | .313 | 12 |

| EMA-0800-106-20 | 10.625 - 10.623 | 9.630 - 9.620 | 1/2 | 4 | 8.095 - 8.093 | 8.5 | 1.781 | .313 | 12 |

| EMA-0950-106-20 | 12.250 - 12.249 | 11.130 - 11.120 | 1/2 | 4 | 9.533 - 9.531 | 10 | 1.781 | .313 | 12 |

| EMA-1150-106-20 | 14.250 - 14.247 | 13.005 - 12.995 | 1/2 | 6 | 11.253 - 11.250 | 11.75 | 2 | .375 | 12 |

In addition to our standard Multiple Disc Electric Clutches, our engineering department can custom design and manufacture a new component to meet your specific requirements. If you have further questions or would like to discuss your specific needs, please contact us.

Images & Drawings

Features of EMA Electric Clutches

Carlyle Johnson's multiple disc electric clutches feature our "through-the-disc" magnetic flux path, which provides maximum torque transfer, automatic wear compensation and consistent performance throughout the life of the clutch. These units can run dry or in oil, for additional heat dissipation and extended disc life.

Time-tested and ruggedly-built, CJM electric clutches utilize highly efficient magnetic flux circuits. These clutches provide fully self-adjusting operation, up to the point of replacement of friction discs, after long service. As with all electric clutches, disc replacement can be done easily and without special tools.

The unit's coil housing, supported on dual ball bearings, is stationary and is held from rotating by electrical conduit or fixed member engaging the threaded fitting. There are also no slip rings or brushes. Since the clutch is a complete, compact and self-contained unit, it is ideally suited to many "built-in" installations.

Advantages

- Highest torque in the smallest space

- Exclusive floating disc pacs for lowest drag, consistent release

- Stationary field eliminates brushes & rings

- Computer designed magnetic flux circuits

- Complete, compact, self-contained unit

Operation

- Through-the-disc magnetic flux path

- Self adjusting for wear

- Positive engagement / disengagement possible at any speed

- Operate in oil or dry applications

Customization

- Available with custom designed magnetic flux applications

- Various electric controls are available for faster actuation and release, and controlled acceleration and deceleration

- Higher torques available

- Custom designs and alterations available

Downloads

Upload a CAD for a custom electric clutch design.

Further downloads including certificates, instruction manuals and product images are available to you in our Download Center:

Downloads