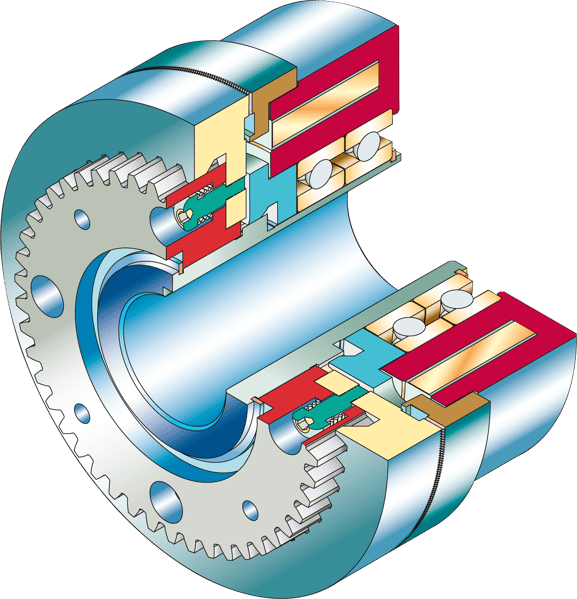

Electric Jaw Clutches / Tooth Clutches (JEB)

Jaw Clutches are designed to optimize size and space in your application. They are ideally suited for positioning, holding and indexing as well as situations that require the unit to maintaining positive registration between input and output shaft.

With pins available for single-position engagement, an electric jaw clutch is often used in applications that require exact positioning, including printing and labeling.

As with all standard CJM electric clutches, our jaw clutch products may be modified for special uses, and we can custom design a solution for your application. Our experienced engineers are ready for your toughest challenges.

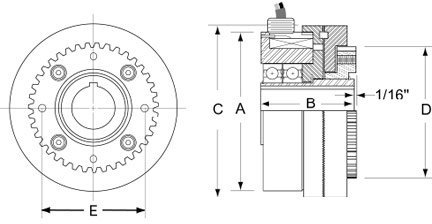

Specifications / Dimensions

| Jaw Clutch Dimensions | Adapter Flange Mounting Dimensions | ||||||

| Model | Coil Diameter* A |

Length B |

Jaw Diameter C |

# of Screws | Screw Size | Pilot Diameter D |

Bolt Circle E |

|---|---|---|---|---|---|---|---|

| JEB0375 | 3.797 | 2.563 | 4.047 | 3 | 1/4-20 | 3.226 or 3.222 | 2 1/4 |

| JEB0425 | 4.359 | 2.750 | 4.625 | 3 | 1/4-20 | 4.059 or 4.055 | 3 |

| JEB0475 | 4.828 | 3.063 | 5.188 | 4 | 1/4-20 | 4.059 or 4.055 | 3 3/16 |

| JEB0625 | 6.359 | 3.625 | 6.750 | 4 | 1/2-13 | 5.975 or 5.970 | 4 1/2 |

| JEB0800 | 8.094 | 4.063 | 8.500 | 6 | 3/8-16 | 7.375 or 7.370 | 5 1/2 |

| Model | Static Torque (lb. ft.) | Teeth (qty) | Bore Min. (in.) | Bore Max. (in.) | Keyway (in.) | Engagement Speed Max. (rpm) | Operating Speed Max. (rpm) |

|---|---|---|---|---|---|---|---|

| JEB0375 | 60 | 360 | 3/4 | 7/8 | 3/16 x 3/32 | 100 | 5000 |

| JEB0425 | 70 | 360 | 1 | 1 1/8 | 3/16 x 3/32 | 100 | 5000 |

| JEB0475 | 150 | 560 | 1 1/4 | 1 3/8 | 1/4 x 1/8 | 100 | 5000 |

| JEB0625 | 300 | 560 | 1 3/4 | 1 7/8 | 3/8 x 3/16 | 100 | 4200 |

| JEB0800 | 600 | 360 | 2 | 2 1/4 | 7/16 x 7/32 | 100 | 3600 |

| Model | Coil Voltage* (VDC ± 10%) | Coil Power** (watts) | Coil Max. Temp. (°C) | Clutch Inertia (lb-ft/sec2) | Clutch & Adapter Inertia (lb-ft/sec2) | Angular Backlash |

|---|---|---|---|---|---|---|

| JEB0375 | 100 or 24 | 45 | 200 | .0004 | .0011 | 1.0° |

| JEB0425 | 100 or 24 | 44 | 200 | .0009 | .0021 | 1.0° |

| JEB0475 | 100 or 24 | 62 | 200 | .0016 | .0036 | 1.5° |

| JEB0625 | 100 or 24 | 62 | 200 | .0059 | .0123 | 1.5° |

| JEB0800 | 100 or 24 | 76 | 200 | .0175 | .0343 | 2.0° |

In addition to our standard Electric Jaw Clutches / Tooth Clutches (JEB), our engineering department can custom design and manufacture a new component to meet your specific requirements. If you have further questions or would like to discuss your specific needs, please contact us.

Images & Drawings

Features of Tooth Clutches & Electric Jaw Clutch Units

Electric Jaw Clutches are available with either 24 or 100 volt DC coils as standard equipment, though other voltages are available to meet your needs. Carlyle Johnson stocks coils with voltages ranging 6 to 240 volts DC.

CJM jaw clutch products feature bi-directional operation, meaning operation is not dependent on rotation. Pins are also available with these designs to permit single position engagement.

Advantages

- Highest torque in smallest space

- Positive tooth drive assures secure engagement with minimum backlash

- Hardened jaws have teeth of high-carbon alloy steel for positive tooth drive

- Exclusive "Power Pack" control ensures quick-acting engagement, release

Operation

- Torque range 60 lb. ft. - 600 lb. ft.

- Bi-directional operation

- Drag-free neutral, no torque transmitted in the disengaged mode

- Engaged fully by induced magnetic flux

Customization

- Torque range 60 lb. ft. - 600 lb. ft.

- Bi-directional operation

- Drag-free neutral, no torque transmitted in the disengaged mode

- Engaged fully by induced magnetic flux

.png?width=541&height=705&name=Electric%20or%20Electromagnetic%20Jaw%20Brakes%20(JEB).png)